Plating Equipments

|

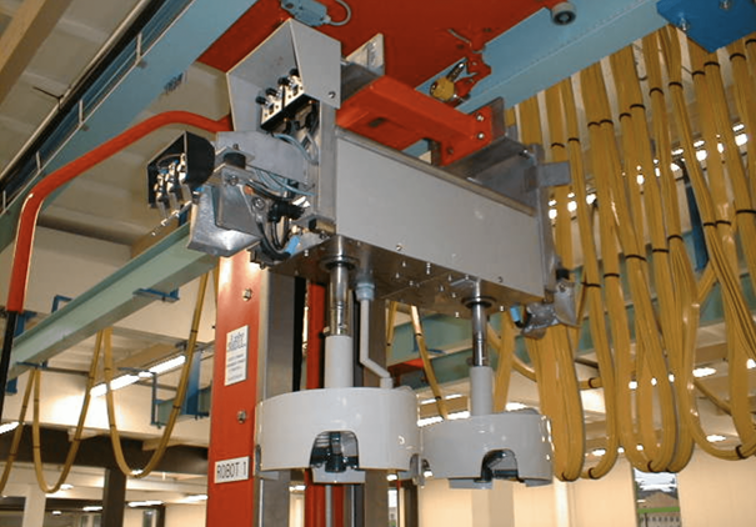

Vibration Plating Device

Small parts do not conduct electricity well in the plating barrel due to large resistance, and it causes the solution to be heated up quickly. Moreover, the barrel in plating process, on account of the small hole of barrel's outer wall, the circulation of the solution between barrel inside and outside is slow, which is not good for the replenishment of metal ions, resulting in uneven thickness of the electroplated layer. Although it can be improved by lower current density, but it will reduce the output. In addition, when the barrel rotates, it produces a large impact on small parts, affecting the precision of the processed parts, and thus affecting the improvement of production efficiency.

Advantages of vibration plating device

This device is the electroplating hardware by adopting the electromagnetic vibrator equipped with frequency inverter, which can make the vibrator producing high-frequency vibration with stepless frequency-adjustable. It has the characteristics of vibration electroplating and intermittent current electroplating. It not only improves the allowable current density, but also can obtain a finely crystalline coating, which also makes the application range of the equipment wider, and it is particularly suitable for precious metal electroplating, especially on the small parts.

Advantages of vibration plating device

This device is the electroplating hardware by adopting the electromagnetic vibrator equipped with frequency inverter, which can make the vibrator producing high-frequency vibration with stepless frequency-adjustable. It has the characteristics of vibration electroplating and intermittent current electroplating. It not only improves the allowable current density, but also can obtain a finely crystalline coating, which also makes the application range of the equipment wider, and it is particularly suitable for precious metal electroplating, especially on the small parts.

![]()